How to Ensure Proper Ventilation for a Resin Printer

Resin 3D printing is notorious for two things: incredible detail and the release of Volatile Organic Compounds (VOCs) and Ultrafine Particles (UFPs). Prolonged exposure to these emissions can irritate the respiratory tract, skin, and eyes, and in professional settings, it introduces potential chronic health risks.

A truly effective strategy doesn’t just move air around; it lowers exposure levels while maintaining the stable environment your printers need to perform. This guide breaks down the science, risk assessment, system design, and ROI to provide a practical, executable blueprint for air quality management.

Health Risk Assessment & Regulatory Framework

Know Your Chemistry.

The starting point is understanding exactly what you are breathing. You need to identify the chemical makeup of your specific resins and their gas release profiles during the exothermic reaction of curing.

Different formulations release different cocktails of acrylates, monomers, and photoinitiators. Short-term spikes in exposure can cause headaches and dizziness, while chronic exposure is a liability for the nervous and immune systems.

Actionable Steps:

- Review the SDS: Don’t just file the Safety Data Sheets; use them to map out a risk hierarchy based on the specific toxicity of your materials.

- Check Local Codes: Align your plan with OSHA guidelines (or local equivalents) regarding Permissible Exposure Limits (PELs) and air exchange rates.

- Set Metrics: Define your target—whether it’s a specific ppm threshold for VOCs or a required number of Air Changes Per Hour (ACH). You cannot manage what you do not measure.

Core Design Principles

Containment and Isolation

The ideal system draws a hard line between the “dirty” air inside the print zone and the clean air in the operator’s breathing zone. The goal is source capture—preventing fumes from ever circulating into the general room. This is usually achieved through negative-pressure enclosures or spot extraction.

Targeted Filtration

Not all filters are created equal. You need a dual-threat approach:

- Activated Carbon: Specifically treated or “modified” carbon is required to adsorb the chemical VOCs.

- HEPA/ULPA: These are essential for trapping the ultrafine particles generated during the print process.

Balancing Energy and Comfort

Venting 100% of your climate-controlled air outside is expensive and can cause temperature fluctuations that ruin prints. The system must balance adequate airflow with energy efficiency and noise control. Smart, variable-speed fans are key here.

Implementation Paths

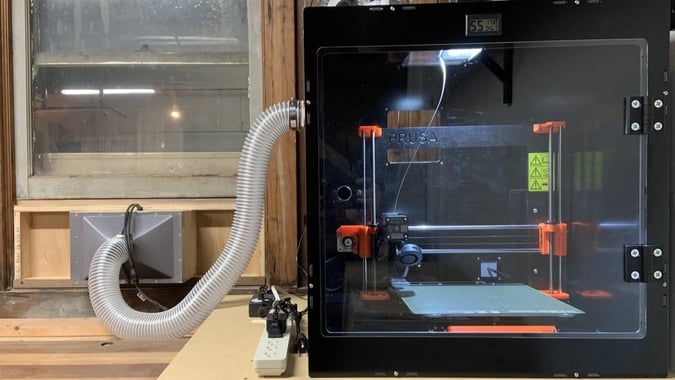

The Basic Setup (Education/Small Prototyping)

- Strategy: Natural ventilation aided by spot extraction.

- Setup: Placing printers near windows with window-mounted exhaust fans, supplemented by portable desktop purifiers.

- Pros/Cons: Low cost and fast to deploy, but lacks precision. Requires constant air quality monitoring.

The Intermediate Setup (Professional Studios/Labs)

- Strategy: Enclosed workspaces with negative pressure and dedicated filtration.

- Setup: Printers are housed in fume hoods or enclosures connected to a ducting system. This is where dedicated, purpose-built hardware becomes critical.

The Advanced Setup (Industrial Production)

- Strategy: Dedicated HVAC integration with external venting towers.

- Setup: A combination of source capture (at the printer level) and room-wide filtration. This involves multi-stage scrubbers (Carbon + HEPA + Chemical adsorption) and external exhaust stacks that meet environmental EPA emission standards.

Smart Monitoring Integrate sensors for VOCs, PM2.5, and temperature into a central dashboard. Data-driven management allows you to ramp up fan speeds only when necessary, extending filter life and maintaining stable thermals.

Execution: Critical Steps and Technical Key Points

- Site Assessment: Don’t guess. Calculate the room volume, the number of printers, and the total surface area of liquid resin. Use this to determine the required CFM (Cubic Feet per Minute) for your fans.

- Equipment Selection: For educational settings, prioritize ease of use. For production, prioritize filter capacity and maintenance intervals. Ensure air intakes and exhausts are positioned to prevent “dead zones” where gas accumulates.

- SOPs (Standard Operating Procedures): Technology fails without protocol. Train staff on when to wear respirators (PPE), how to handle waste, and how to react if a ventilation failure occurs.

- Validation: Once installed, test it. Use handheld smoke testers to visualize airflow and confirm negative pressure. Verify that noise levels allow for comfortable conversation.

- Maintenance: Schedule filter changes before they reach saturation. A clogged filter is worse than no filter because it gives a false sense of security.

Coupling Materials and Process

Resin-Specific Filtration

Standard resins and engineering resins have different odor profiles. If you are printing with high-performance materials that use stronger solvents or monomers, ensure your carbon filters are rated for those specific compounds.

Post-Processing

Operators often focus on the printer, but the washing station (IPA evaporation) and the curing oven (off-gassing) are often the biggest VOC contributors.

Waste Management Integration

Fumes come from liquid waste, too. Ensure your ventilation covers the hazardous waste storage area where used IPA and resin-soaked towels are kept.

Cost Analysis and Value

CapEx vs. OpEx

An advanced ventilation system has a higher upfront cost (CapEx), but it reduces Operational Expenditure (OpEx) by preventing employee health issues, reducing sick leave, and ensuring print stability (fewer failed prints due to temperature swings from opening windows).

Risk Mitigation

Quantify the cost of downtime or potential OSHA fines. A robust system pays for itself by ensuring business continuity. Position the ventilation upgrade as an asset protection strategy, not a utility bill.

Conclusion

Ventilation in resin 3D printing is about creating a sustainable, professional environment. By rigorously assessing risks, choosing the right equipment—like the specialized HeyGears GreenPrint Purification Unit—and establishing strict maintenance protocols, you transform a hazardous variable into a controlled, reliable part of your production line.

For any organization serious about scaling their additive manufacturing, the next step is clear: Audit your current airflow, define your safety metrics, and invest in a system that protects your most valuable assets—your people and your process.