Steam Boiler Maintenance Tips: Keeping Your System Efficient and Safe

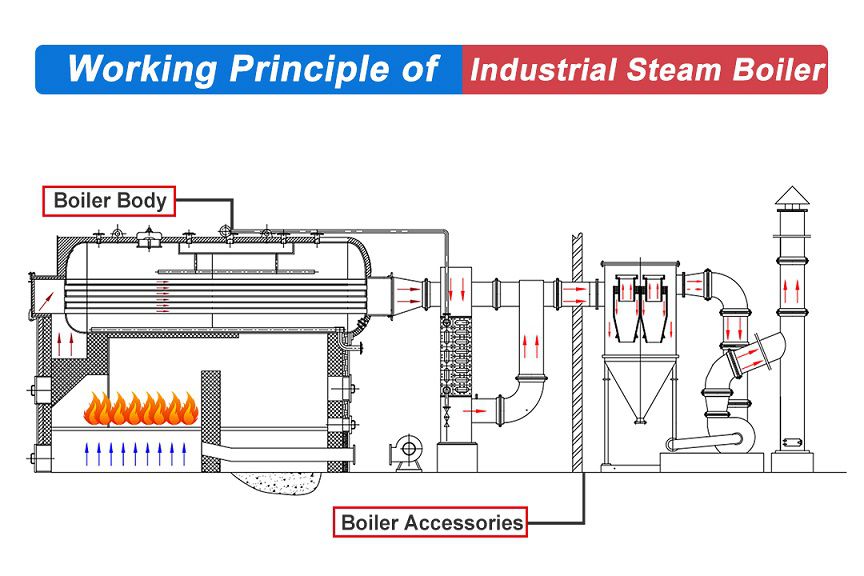

Steam boilers are key parts in many factories for heating setups and production places. Taking good care of them helps them work well and last longer. Most of all, it stops risky problems from happening. Knowing how you look after your steam boiler keeps you safe at work and saves a lot of money on fixes.

Inspect Heat Exchanger Surfaces

The heat exchanger is at the center of your steam boiler; thus, it moves heat to water. Over time, dirt and other build-up can make a layer on these surfaces. This layer keeps heat from passing through and causes the system to work less well. Steam boiler industrial you should make time for regular checks to see how much has built up and clean these areas when you need to.

To do this, use the right brushes or chemical cleaners made for your type of boiler. A small amount of buildup can change the usage of boilers. This is why keeping the heat exchanger clean is so important for the way your boiler works.

Conduct Routine Blowdown Procedures

Blowdown is done to take out dissolved solids and dirt that build up in a boiler. This stops them from piling up, which can slow things down and harm the parts of the system. Bottom blowdown is used to get rid of sunken sludge and dirt. Surface blowdown takes out dissolved solids sitting on the top of the water. You should have a blowdown plan.

This plan should be based on what the water tests say and what the maker of the system says to do. Some systems must be blown down every day. Other systems with really good water may not need it so often. Always do this important step and do not skip it. If you do not, solids can build up and cause things to overheat, pipes to break, and repairs to cost a lot of money.

Examine Fuel System Components

Your boiler’s fuel system needs regular care to work well. You should look at the fuel lines and nozzles for blockages or damage; so clean or change the fuel filters when it’s time, so fuel can move easily.

For gas systems, you need to make sure the gas pressure is right and look at the burner flames. They should show the right color and shape.

If you have an oil boiler, clean the nozzle often and check the atomizer. When fuel does not get to the boiler or burns in the right way, it can waste energy and make the cost go up. It can also be unsafe for people.

Inspect Insulation and External Components

External Maintenance Checklist:

- Look at insulation: Find out if any insulation is broken, wet, or not there.

- Look at door seals: Switch out old seals. This helps stop heat from getting out.

- Look at parts that hold things up: Make sure everything is strong.

- Clean outside surfaces: Take away dust and dirt. This will help with how heat moves away.

- Look at vent systems: Make sure air goes out the right way, and look at the stack.

Schedule Professional Annual Inspections

Doing small jobs each day and week helps your system work well. But once every year, you need a professional to check everything. A person who knows the rules, called a certified technician, looks inside the tubes that use sound tests for thickness and checks all the safety parts to make sure they work. They can spot problems like rust or things that could break before they turn into big troubles.

A real check-up also helps you follow local rules and what insurance wants. Keep notes for every check, fix, or work done. This helps you know if your system is doing well and shows people you follow the rules.

You have to pay close attention and follow the set steps when you take care of your steam boiler system. Make sure you have experts check your boiler as planned. Doing all this will help your system run well and stay safe to use. Steam boiler industrial checkups cost less to stop problems before they happen, so having a good plan for upkeep helps your building stay safe and keeps things working the way they should.